Wool has been consistently used in clothing for thousands of years. It’s one of the most versatile materials for suiting. In this guide to wool fabrics for suiting, we’ll explain the following:

- How wool is produced and the different types and qualities of wool

- The benefits of wool as a material

- The Super numbering system used in wool

- Wool cloth weight and weight guide

- The common weaves used in wool fabrics

- Choosing the right wool material for your suit

- How to maintain your wool suit

How is wool produced?

Wool is an animal fiber that’s produced from sheep, goats and a range of other animals including camelids such as alpaca. When wool is produced from other animals than sheep, it’s given a specific name. Cashmere and mohair are produced from goats, angora from rabbits, vicuña from the eponymous animal, and so on.

Wool is produced from two types of follicles in skin cells, but differs from hair in that wool has crimp and is elastic. What we use in wool fabrics is termed true wool fiber, which are finer and do not naturally shed. They must be shorn. Shorning wool is important for the health of the sheep. An unshorn sheep not only suffers discomfort due to the weight and matting of the wool, but can trap sticks, twigs and insects that can hurt it. Last year, an Australian sheep named Baarack was rescued in Victoria, Australia, having been unshorn for over 5 years. It had 75 pounds of fleece removed, a world record.

Shearing and Classing Wool

The shearing of sheep can be done in many different ways. A shearer uses a mechanical device and starts by removing the belly wool before removing the fleece from the sheep. This is done harmlessly. Another method is to inject a protein that causes the wool to naturally break, after covering the sheep with a net to collect the wool. Within a week, the fleece is separated and can be removed by hand. The finest fleece tends to be from the shoulders and sides.

Once the raw wool (as it is known in the industry) is removed, it’s skirted using rollers to separate short hairs and other bits from the fleece. These are used for other purposes where wool’s thermal resistance is valued. It is then classed, collected and baled.

The classing of wool is done by a professional classer, and determined by various factors. The first is the breed of the sheep, as certain breeds tend to produce wool fibers of particular quality. These include Merino, Panama, Cormo, Rambouillet and Lincoln sheep.

A second factor is the spinning quality and this is determined by the crimp and elasticity of the fleece. The crimp refers to the number of bends in the wool fiber and its elasticity is how well it stretches. These affect the ability of wool to be spun into yarn, and the quality of the yarn when it’s spun. The crimp of the wool also determines how well it traps air. In fine merino wool fabrics, there can be up to 40 crimps per centimeter of fiber.

Other factors include the tensile strength of the raw wool, its color and if there are stains. Classing ensures that the wool fibers are consistent in a bale, so that the wool fabric woven from it will be of a consistent quality.

Why choose wool?

As mentioned previously, wool is a versatile and highly sustainable material that’s used in suiting. It’s highly renewable as it’s naturally produced from sheep, is naturally water repellent due to the lanolin in the wool, and easily biodegradable.

The wool used by Officine Paladino for our suiting fabrics are sourced from farms that practice full traceability and practice sustainable, organic farming methods to ensure that the land and animals are well cared for. Increasingly, today’s farms provide a high quality of animal welfare, which ensures the wool produced from them is of a high quality as well.

The mills we work with are also dedicated to sustainability, from their energy use to the choice of chemicals used in the processing of raw wool, dyeing and weaving. Producing wool yarn also requires the lowest amount of water usage per yard or meter, compared with other yarns.

The benefits of wool

Wool has numerous qualities that make it ideal for suiting across the seasons. Like all the natural fibers that we use in our fabrics, wool is biodegradable, sustainable and long-lived. In addition, wool fabrics also have the following values.

It’s a breathable fabric

The crimp of a wool fiber, as it traps air, makes wool ideal for warmth. Yet depending on how it’s woven, it also ensures high breathability in the fabric. With a loose plain weave such as a hopsack fabric, it can be a suitable material for suiting even in the height of summer, while a twill weave makes it great for winter coats.

It’s crease-resistant

The elasticity and tensile strength of a fine merino wool fabric gives it a natural stretch and durability, so they can be worn for years without damage. In the spinning of wool, the tensile strength and elasticity determines its ability to be lightly twisted. Such high twist yarns offer crease resistance to the wool fabric that’s produced.

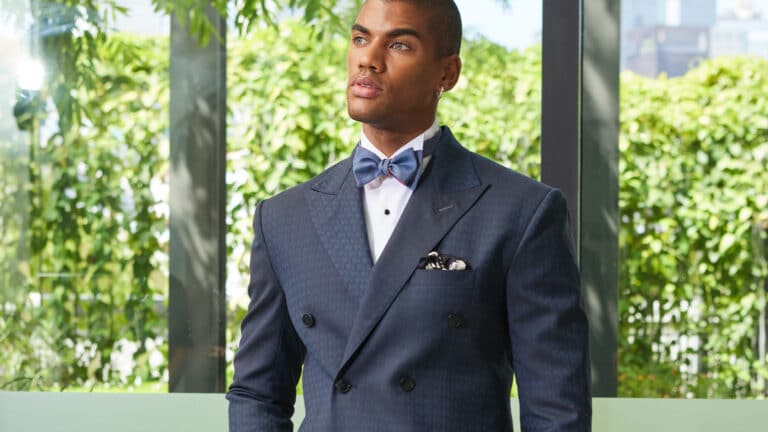

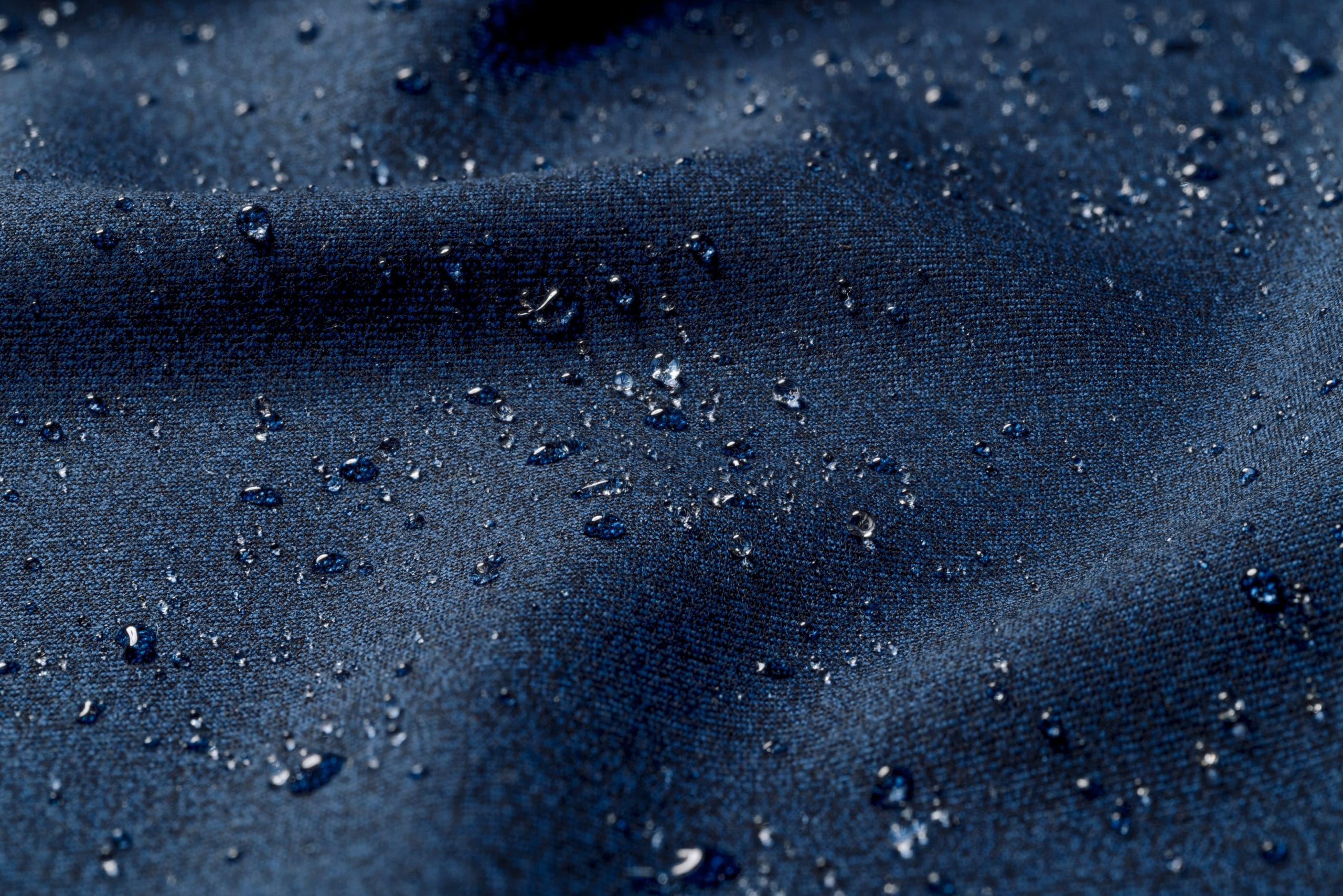

It’s water-repellent

The sebaceous glands of sheep and other wool-producing animals produce lanolin with the wool. It’s considered a wax or oil that offers waterproofing qualities, which help sheep to shed water from their coats in the rain. In the process of shearing, the lanolin that coats the wool fibers continue to offer the same protection to the final wool fabric, giving it some water-repellent quality. Lanolin also makes wool rather stain repellent in its natural state and passes on this quality during processing to the final fabric, ensuring that it has great longevity.

It’s thermal-resistant

Wool also possesses other qualities that makes it ideal for particular clothing where thermal resistance is important. It burns at a higher temperature than cotton or other synthetic fibers, with a lower rate of spread and heat releasing. It forms a char that’s self-extinguishing and therefore is useful in high safety environments or in garments for firefighters, who are often exposed to high heat environments.

How are wool fabrics produced

Raw wool is spun into two types of yarns: woollen and worsted. Woollen yarns go through two processes: carding, which untangles the fibers and passed through rollers with fine teeth, to smoothen out the yarn. Then it’s oscillated with one fiber diagonally overlapping another to create a criss-cross effect.

Worsted yarns go through carding, followed by gilling and combing which adds moisture and lubricants, and aligns the fibers before doubling. Shorter fibers are removed in the process and longer fibers are straightened. They are then drawn, which is the process of doubling the sliver of wool fibers and then twists, winds and thins them. Finally it’s lightly twisted, giving rise to the term high twist. Worsted yarns are finer, smoother and crease-resistant. Two main types of weaves are used in the production of our worsted wool fabrics: the plain weave and twill weave.

Botticelli OP 2110 is a plain weave wool fabric with a micro-check pattern and a very soft touch.

Plain weave wool fabrics

The plain weave is the most common type, with interlacing warp threads that run lengthwise and are held in place. Weft threads that run horizontally go over and under the warp. This creates an interlocking pattern that is very durable, with some stretch and breathability.

Some variations of the plain weave fabric include the hopsack weave, which uses two weft threads that go over and under two warp threads. This is a looser version of the plain weave, creating a fabric that’s ideal for hot summers or warm climates. The weave also means jackets made from hopsack weave wool fabrics are unstructured, lightweight and relaxed.

A more formal type of plain weave is the faille weave, which uses a heavier weft thread, usually of the same colour, to create an interlocking weave over and under multiple warp threads. The faille weave gives a soft texture with a glossy look and feel. It creates a fabric with an excellent handle and is often used in tuxedos.

Blue Haze OP 2001 is an example of a classic twill fabric with a subtle pattern created thanks to the use of multiple thread colors.

Twill weave wool fabrics

The twill or twilled weave is a pattern where the weft threads goes over and under two or more warp threads, and with the pattern shifting by one warp thread with each weft passing. This creates a visible row of diagonal ribs that run parallel on the surface of the fabric.

Twill patterns are either right-handed (or a z-twill) or left-handed (s-twill), running upwards or downwards from the left, respectively. Twill weave fabrics are used in a variety of materials, ranging from denim (cotton-based) to gabardine.

A variation of the twill weave is the herringbone pattern, also known as a broken twill. It has both right- and left-hand twill patterns appearing side by side, creating a chevron-like design in the fabric. Many other patterns are made with twill weave wool fabrics, such as glen plaid, diamond check, dogstooth and more.

The Super numbering system

The key factor defining the quality of a wool fabric is the fineness of the fiber and its length. Merino wool, which is used in our fabrics, are between 12 and 24 microns in diameter. They are differentiated in this manner:

- Over 23 microns: strong merino

- 20.1-23 microns: medium merino

- 18.6 – 20 microns: fine merino

- 15.6 – 18.5 microns: superfine merino

- Below 15.5 microns: ultrafine merino

This is often indicated on the selvedge of the roll of wool fabric. It’s also used as a guide in the commonly-used S-number system. In Australia and New Zealand, a standard known as 1PP is used to indicate superfine and ultrafine merinos of 16.9 microns or less.

The S-number or Super number is a classification system that’s used across different types of wool fabrics. It refers to pure new wool fabrics, as well as those blended with rarer fibers such as mohair, cashmere or silk. In wool blends, they must be at least 45% wool in order to be given a S-number. The S-number relates to the fineness of the wool. The smaller the S-number, the bigger the diameter of the fiber. Starting at Super 80’s that use fibers of 19.75 microns, every 0.5 micron diameter difference goes up a Super number, i.e. Super 90’s is 19.25 microns, Super 100’s are 18.75 microns and so on.

The most popular fabrics in suiting are between Super 100’s to Super 180’s, that run between 18.75 microns to 14.75 microns. Because higher S-number fabrics are made from finer fibers, they also tend to be slightly more fragile compared with lower S-number fabrics. However, they are softer to touch and more precious and expensive. In tailoring, Super 150’s and higher wool fabrics are ideal for formal and fine tailoring, while Super 100’s to Super 130’s are great for regular, everyday wear.

It’s also important to note how Super numbers relate to the maintenance of a suit. A high S-number wool fabric has more fine fabrics per yard or meter, and therefore during dry-cleaning, will lose more of the natural lanolin that coats the wool fibers due to the chemicals used. Lanolin gives wool its sheen, adds to its strength and elasticity and imbues the cloth with some natural water repelling qualities, so with more dry cleaning, Super 180’s wools will change. That’s why tailors recommend to their customers to use such fabrics for suits that are meant for special occasions.

A guide to wool fabric weights

The weight of a wool fabric is determined by the S-number of the wool and the weave of the fabric. The former determines the density of the fibers in the yarn, and the latter the density of the yarn in the fabric. Fabric weights are not limited to wool, and are generally used to gauge specific qualities such as breathability, strength and thermal resistance. These are measured in grams per square meter.

For example, a 140 gram merino wool fabric is a featherweight fabric that’s ideal for warm weather, and would likely rate a very low S-number, and a fabric that’s between 150 -170 grams would be ultralight and suitable all year round. Between 170 – 200 grams, this would be a lightweight fabric, and 200 – 300 grams are a mid-weight fabric that’s suitable for cooler climates. Above that would be winter wear.

Since the fabric weight affects the heft of the material, it would also have an impact on the handle of the cloth, both for the tailor and the wearer. A good handle for wool suits would ideally start from the mid-weight range, giving it a good balance of comfort, allowing the fabric to move with you but still ensuring it keeps its structure. A good handle also makes the fabric easy for tailors to work with, ensuring the tailoring process is even better.

What’s the right wool fabric for your suit?

Consider a lightweight and highly breathable fabric such as our Sandcastle OP 1901 linen, as shown here, for warmer and more humid weather.

For casual suiting or warmer climates

A lightweight plain weave fabric or a hopsack are good choices for casual suiting. Other excellent options include wool-linen or wool-mohair blends that are soft, relaxed and create very unstructured suits with a soft handle. Plain weave fabrics offer greater breathability than twill weave fabrics and therefore are better choices for warm climates. We’d suggest going with a Super 120’s or 130’s, which offers great comfort when worn and doesn’t require a lot of care or maintenance.

A plain weave fabric, such as Nugget OP 2183, with a heavier weight and classic handle, works well for cooler climates.

For formal suiting or cooler climates

A heavier weight plain weave fabric or a twill weave with a fine handle are great choices for such climates and conditions. We’d suggest going with a Super 130’s or 150’s, with a soft touch wool fabric. This makes the fall and drape of the suit excellent when worn, reduces crease and creates a more structured suit that’s ideal for a formal occasion.

How to care for your wool suit

The beauty of wool is not only that it’s a very sustainable and accessible material, but also that it’s easy to care for and use over and over again. Instead of sending your suit to a dry cleaner every time you wear it, which uses chemicals and strips the wool fabric of lanolin, you can simply brush the suit down with a soft brush and air it out overnight to ensure any sweat dries off naturally. Brush it gently again the next day and hang it up.

Many people like to use the hot steam in a bathroom to uncrease a suit if it’s been kept in an overnight bag or luggage bag. In a high quality wool fabric using a high twist wool, there’s no need to take such action. Simply hang it out and it will uncrease; any other creases can be dealt with a steamer.

To keep a suit in its ideal form, a suit frame or stand or a suit hanger can be used to keep it in shape. Where possible, the suit should be kept in a cool environment with lower humidity to prevent mold or other issues.

Check out our A Suited Approach and Eco-Evolution lookbooks to discover some of our luxury wool fabrics designed for suiting. You can also explore how to design your own suit using our online Styling Tool to see what it will look like before choosing the right wool fabric to acquire, or visit one of our partner tailors to create your next suit.